Biomaterials in the biomedical field are materials that are non-toxic and that can interact with the biological system. The Fraunhofer BioRap® team develops biobased as well as synthetic biomaterials for additive freeform fabrication. Research and development activities cover synthesis of crosslinkable monomers and polymers, modification of biomolecules, formulation of printable fluids and solutions, adjustment of viscosity and gelation of inks for various printing processes such as drop-on-demand ink jet, extrusion based dispensing, stereolithography, and two-photon polymerization. Additionally, we offer formulation of tissue specific bioink compositions and testing of cytocompatibility of ink formulations for various cell types.

Printable Biomaterials

Biocompatible polymeric inks

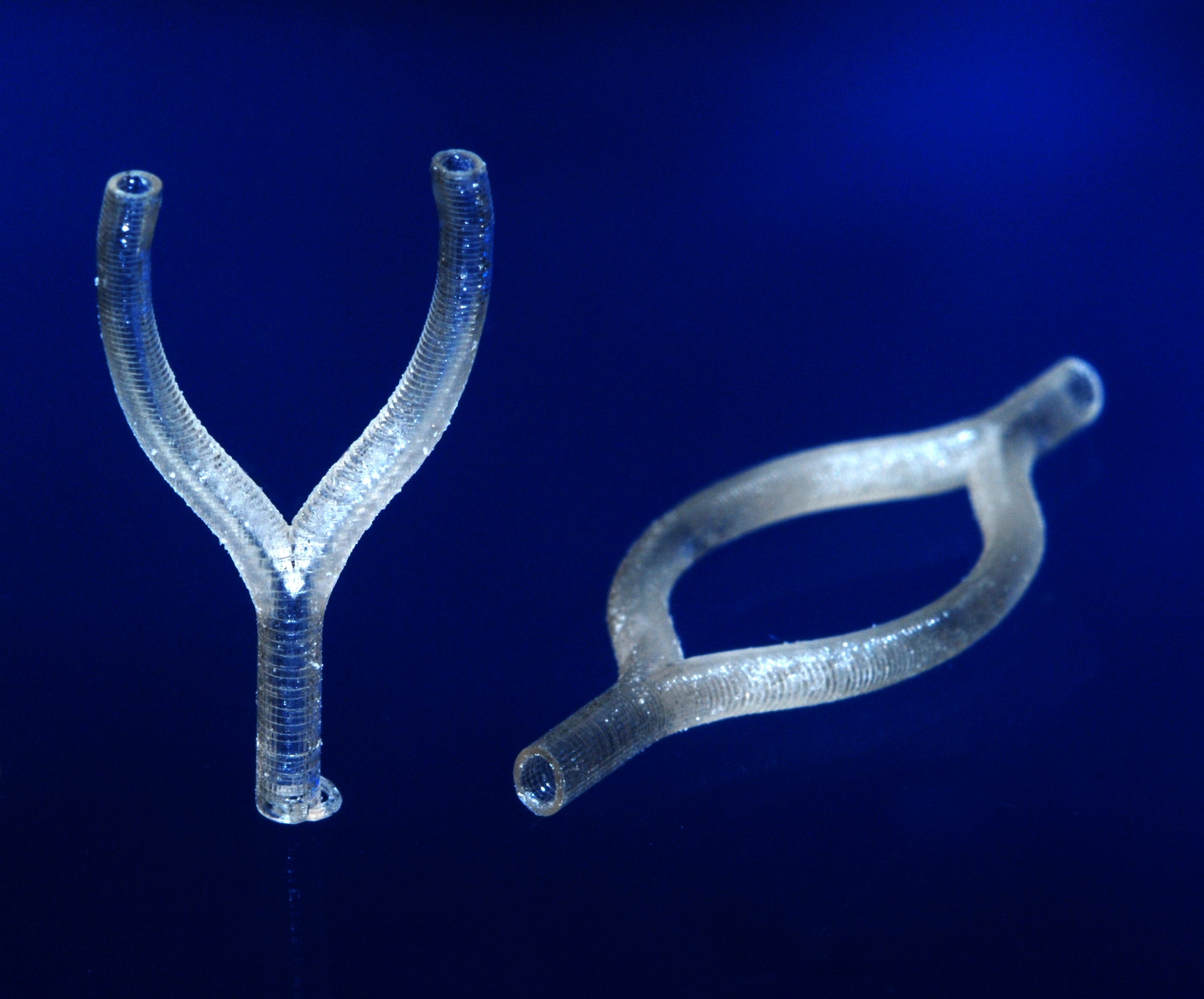

Photo-crosslinked acrylates offer the possibility of developing and supplying suitable materials which meet the requirements of additive manufacturing (AM) and which can be used as materials for medical application fulfilling the requirements of biocompatibility and long-term stability. Their mechanical properties can be adjusted in a wide range and they are suitable for applications ranging from dental fillings to contact lenses.

Synthetic biocompatible resins are a cost effective material class suitable for various AM technologies such as stereolithography (STL, SLA, MPP, TPP), 3D inkjet and extruder dispersion printing techniques.

At Fraunhofer new polymeric and hybrid photo-crosslinkable materials are developed that meet AM process-related boundary conditions, e.g keeping within viscosity limits, achieving three-dimensional UV crosslinking, and curing by visible laser light. The range of developed materials covers up soft elastic materials e.g. for development of artificial blood vessel equivalents to hard bone-like materials. Also (water) soluble or mechanical removable support-materials have been developed.

Biobased bioinks

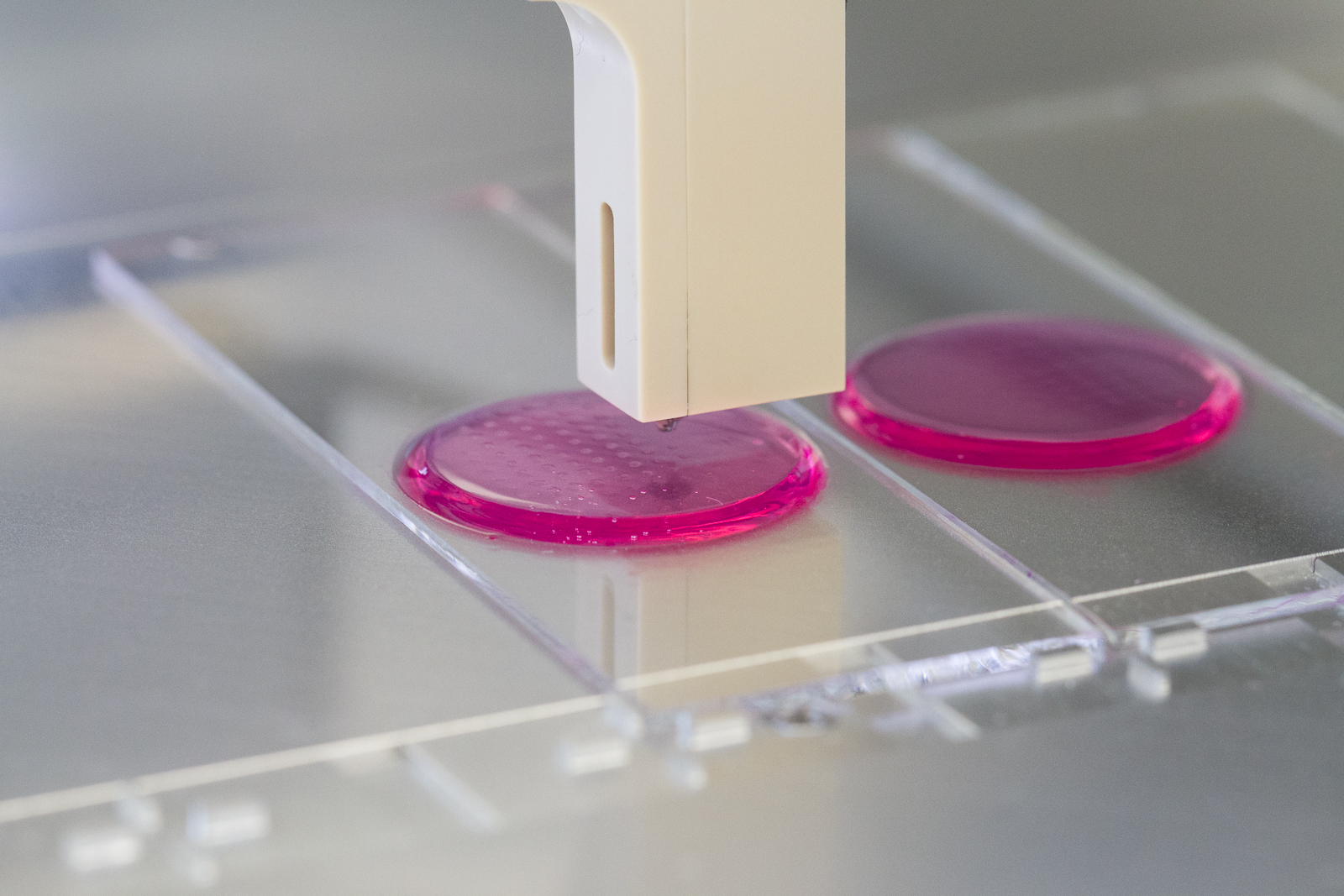

Biomolecules are highly attractive materials which are produced and optimized by nature. They can meet complex challenges such as storage and release of water, biological signalling and even the formation of a biofunctional matrix to host living cells. We can modify biomolecules and use them in material design for bioprinting. We use the biopolymers from the native extracellular matrix in order to provide printable formulations of tissue specific matrices for printing and encapsulation of cells.

Examples for photo-crosslinkable biomolecules: methacryl-modified gelatin derivatives, methacryl- and acetyl-modified gelatin derivatives for non-gelling, low viscous solutions, methacrylated hyaluronic acid or chondroitin sulfate, methacryl-modified or benzophenone-modified heparin.