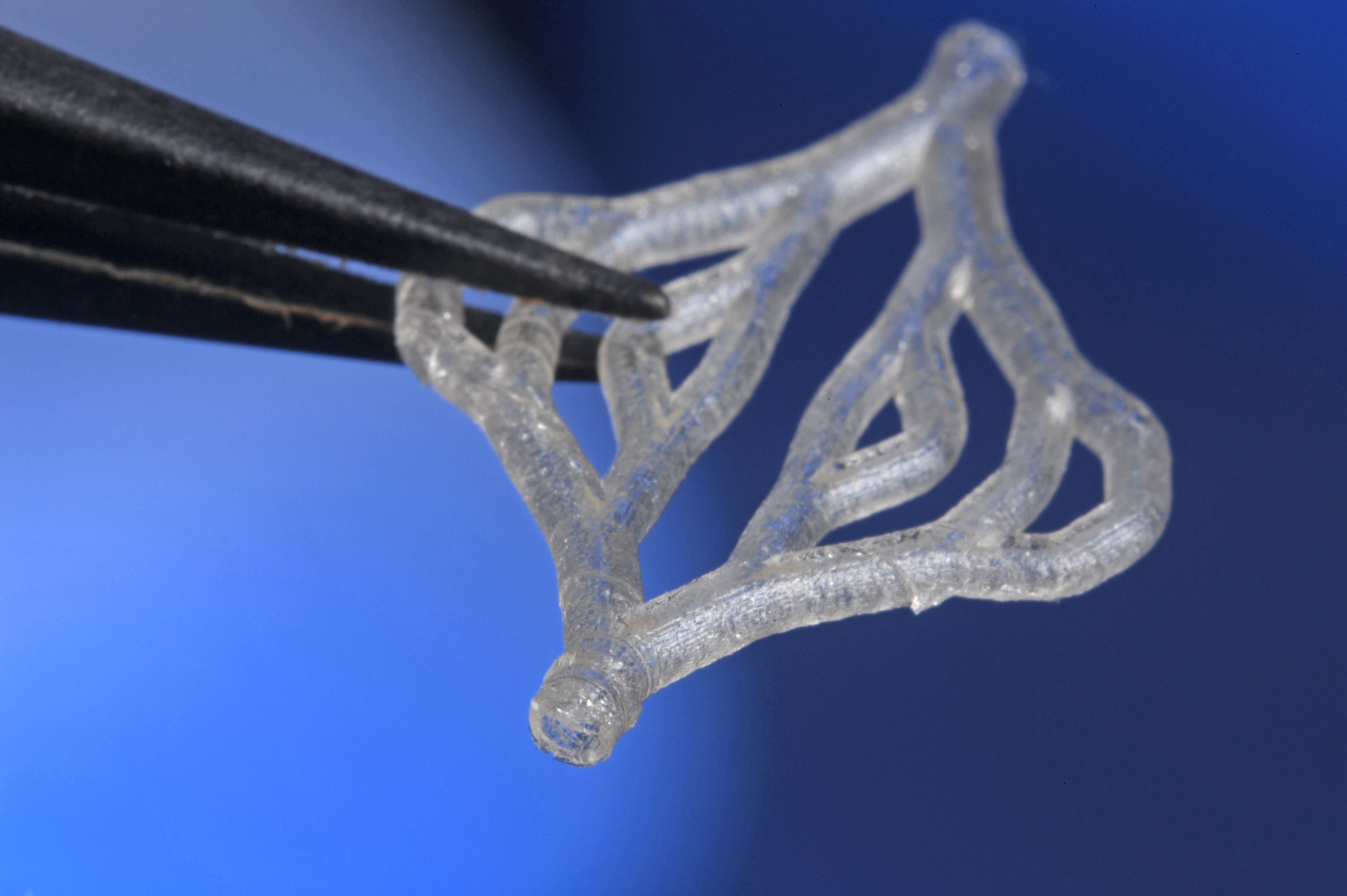

Fraunhofer introduces freeform fabrication for the production of bioinspired flexibel structures from the micrometer to the cemtimeter range applying various additive manufacturing techniques. Digital 3D printing offers huge possibilities for the generation of individualized protheses, implants and models for medical technologies, biomedical applications, tisseu models, and tissue regeneration.

Biofabrication

Freeform Fabrication of three dimensional scaffolds for biofabrication needs processes which are flexible. Photopolymerisation is an opportunity for building complex structures in a layer-by-layer strategy. Different photo-curing technologies allow structuring and generation of scaffolds with increasing resolution depending on the requirements. The technologies range from fast Digital light processing (DLP), Stereolithography (STL) to highest resolution with Two-photonpolymerisation (TPP). Structures from less micrometers to several centimeters can be generated.

Services

Development of new photocuring processes by using new laser sources

- ns-, ps-, fs-laser sources

- tunable wavelengths

- UV-Laser sources

Development of new photopolymer formulations

- Working without Photoinitiator

- Biofunctional surfaces

New machine concepts

- Process combinations

- Combination of laser sources

Patents

Holger Leonards, Andreas Hoffmann, Arnold Gillner; Method and Arrangement for the additive manufacture of components; WO 2016008876 A1 (application).

Publications

- Engelhardt*, S.; Hoch*, E.; Borchers, K.; Meyer, W.; Krüger, H.; Tovar, G.; Gillner, A. (* contributed equally)

Fabrication of 2D protein microstructures and 3D polymer–protein hybrid microstructures by two-photon polymerization.

Biofabrication 3/2 (2011) 25-33. - Engelhardt, S.; Hu, Y.; Seiler, N.; Riester, D.; Meyer, W.; Krüger, H.; Wehner, M.; Bremus-Koebberling, E.; Gillner, A.

3D-Microfabrication of Polymer-Protein Hybrid Structures with a Q-Switched Microlaser.

Journal of Laser Micro/Nanoengineering 6/1 (2011) 54-58. doi: 10.2961/jlmn.2011.01.0012. - Leonards, H.; Engelhardt, S.; Hoffmann, A.; Pongratz, L.; Schriever, S.; Bläsius, J.; Wehner M.; Gillner, A.

Advantages and drawbacks of Thiol-ene based resins for 3D-printing.

Proc. SPIE 9353, Laser 3D Manufacturing II, 93530F (March 16, 2015); doi:10.1117/12.2081169 - Meyer, W.; Engelhardt, S.; Novosel, E.; Elling, B.; Wegener, M.; Krüger, H.

Soft Polymers for Building up Small and Smallest Blood Supplying Systems by Stereolithography.

J. Funct. Biomater. 3 (2012) 257-268.