Fraunhofer BioRap® Technology Platform

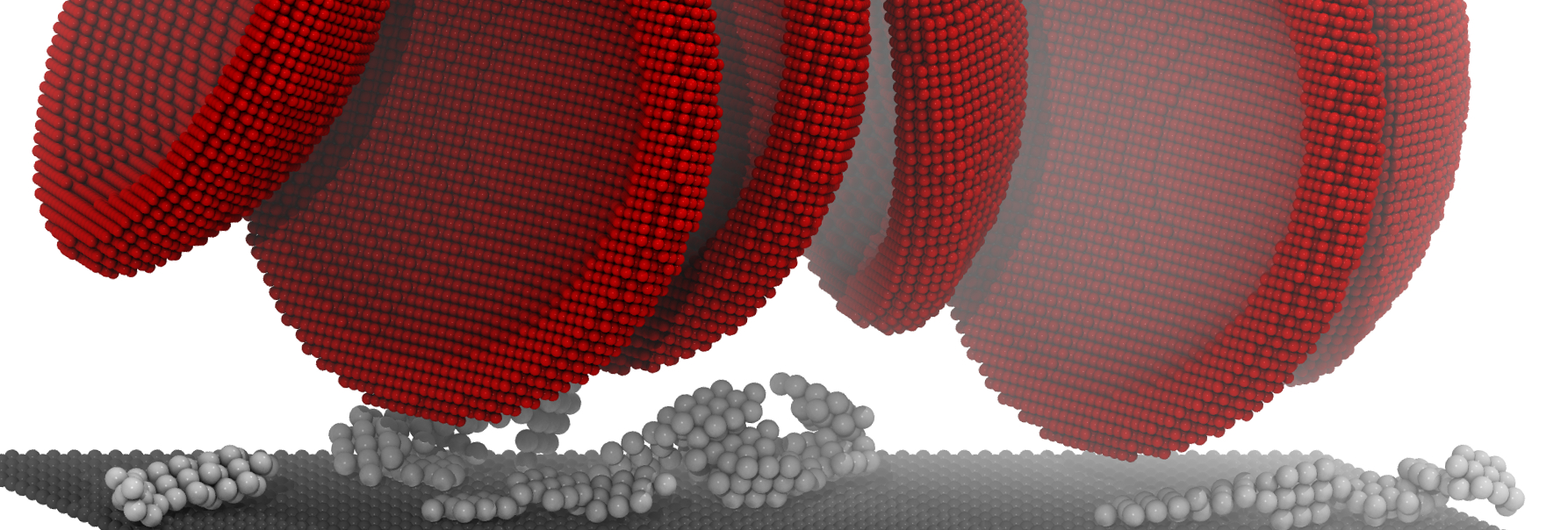

Digital manufacturing of bioinspiried, biofunctional, and biobased structures

Nature continually optimizes materials and structures to fulfill complex and multiple functions. We want to develop artificial structures which perform as well as natural ones. In order to do so we need

- fabrication processes that do not set narrow limits to the generation of structures and shapes

- materials that allow for tailoring of their physical, chemical, and biological properties.

Fraunhofer develops tools for digital biofabrication in an interdisciplinary team. We introduce freeform fabrication in a new dimension for the manufacturing of flexible structures from the micrometer to the centimeter range. We develop new biocompatible materials, algorithms and manufacturing processes for implants and bioartificial tissues based on matrix and cells.